10 Best Wheel Bearing Greases 2026 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

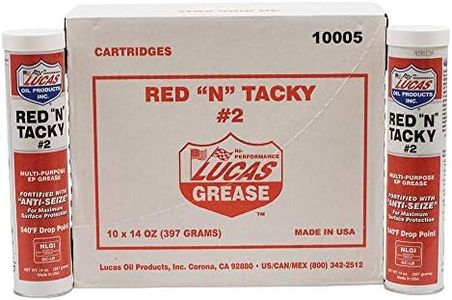

Stens Lucas Oil Red N Tacky Grease, (10 Pack)

The Stens Lucas Oil Red N Tacky Grease is a solid choice for those looking for dependable wheel-bearing grease. One of its most appealing strengths is its long storage life, which means you can buy this 10-pack and not worry about it losing effectiveness while waiting for use. This makes it a practical option for anyone who wants to maintain their equipment without the hassle of frequent repurchases. Its excellent mechanical stability ensures it performs well under extreme conditions, so it can handle heavy usage without breaking down.

On the downside, while it is designed as a direct OEM replacement and specifically tailored for certain models, it may not be compatible with all types of machinery. Users looking for a universal grease might find this a limiting factor. Additionally, while the bulk packaging is cost-effective, storing 10 tubes may be excessive for occasional users or those with smaller projects.

The Stens Lucas Oil Red N Tacky Grease is a robust lubricant that's particularly beneficial for heavy-duty vehicle owners and those who need reliable performance over time. However, potential buyers should consider their specific equipment needs before committing to this grease.

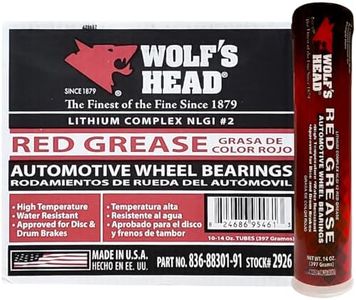

Wolf's Head Red Grease NLGI #2 (836-88301-91) 14 Oz Tube, Pack of 10

Wolf's Head Red Grease NLGI #2 is a tacky grease designed to stay in place, making it ideal for wheel bearing and chassis applications. Its high water wash-out resistance is a strong point, ensuring it performs well in wet conditions. With NLGI GC-LB certification, it's suitable for both wheel bearings and general chassis lubrication, meeting industry standards for quality and performance.

The grease offers outstanding protection against rust and corrosion, which is essential for the longevity of mechanical parts. Additionally, oxidation inhibitors allow it to operate at temperatures up to 150°C for extended periods, making it versatile for various temperature conditions. The excellent protection against failures caused by shock loading is another notable benefit, especially in high-stress environments.

The 14 oz tube size in a pack of 10 offers good value and convenience for those needing a larger supply. This grease performs well across the essential specs and is particularly beneficial for users needing reliable, high-temperature, and water-resistant lubrication.

AtomLube Ultra Heavy Duty Red Grease, 2-Pack of 14 Oz. Tubes| Waterproof & High Temp Lubricant | Wheel Bearing Grease for Semi Truck Accessories

Most important from

2346 reviews

The AtomLube Ultra Heavy Duty Red Grease is designed to meet the rigorous demands of wheel-bearing applications, making it suitable for semi truck accessories. This grease stands out for its high-performance specifications, including its ability to handle extreme pressures and high temperatures, which is significant for heavy-duty use. The product's waterproof properties ensure it maintains its functionality even in wet conditions, preventing washout and corrosion. This is beneficial for maintaining the longevity and performance of the equipment it is used on.

The grease also adheres well to metal surfaces, providing strong protection and reducing the need for frequent reapplication, which translates to longer lubrication intervals and extended equipment life. Its compliance with the National Lubricating Grease Institute (NLGI) GC-LB performance classification further reassures its suitability for automotive applications in wheel bearings and chassis. For most general and heavy-duty automotive applications, this grease appears to be a reliable and robust choice.